In this guide, you will learn about things you should and shouldn’t do when delivering truckload to Amazon’s FBA centers.

For every LTL and FTL shipment sent to Amazon, there are certain requirements that shippers and carriers are responsible to complete.

*These requirements apply to both individual boxes, and boxes loaded on pallets for truck transport.

An Amazon FBA warehouse frequently refused floor loaded containers for one of Freight Right’s clients. The reason for refusal that FBA gave was that the contents are “unsafe to unload.” Freight Right’s Import team contacted the Relay Operations Center (ROC), as well as the FBA facility manager and was able to find out that there were 3 underlying issues with the way the factory in China was loading the containers.

1. To optimize the space in the container, the factory was loading some of the boxes upright, others sideways, and topping them off with another layer of boxes loaded flat. As a result FBA forklift operators were unable to use clamps to unload the boxes.

2. Generally, Amazon would use manual labor to remove the top layer of boxes, leaving the ones facing in the same direction which would be clampable. Unfortunately, at 80-90lbs per box, the goods were too heavy for one person to unload (Amazon and OSHA regulations limit the weight per box to 50 lbs for manual labor).

3. The fact that the boxes were stacked too high in the container made it unsafe for two people to hand-carry the boxes, which made the problem even worse.

The factory, like most logistics operators, was optimizing the space in the container achieving an impressive 90%+ container utilization (See image below). Unfortunately, the results of this seemingly well-intentioned planning resulted in the extra expenses of unloading the refused containers, palletizing, and re-delivering them with two trucks. This was costing the client thousands of dollars for each container.

After the fact-finding calls, Freight Right’s team got to work on some solutions for the customer. We came up with three custom solutions and calculated the landed cost per unit to make it easy for the customer to make a decision.

Solution #1:

Keep the containers loaded at 90% utilization but deliver it to one of Freight Right’s warehouses where the boxes would be transloaded, palletized, and delivered to Amazon with larger trucks. This would allow Amazon to unload using regular forklifts and avoid refusals. The container would fit 402 units with a landed cost per unit of $19.46.

Solution #2:

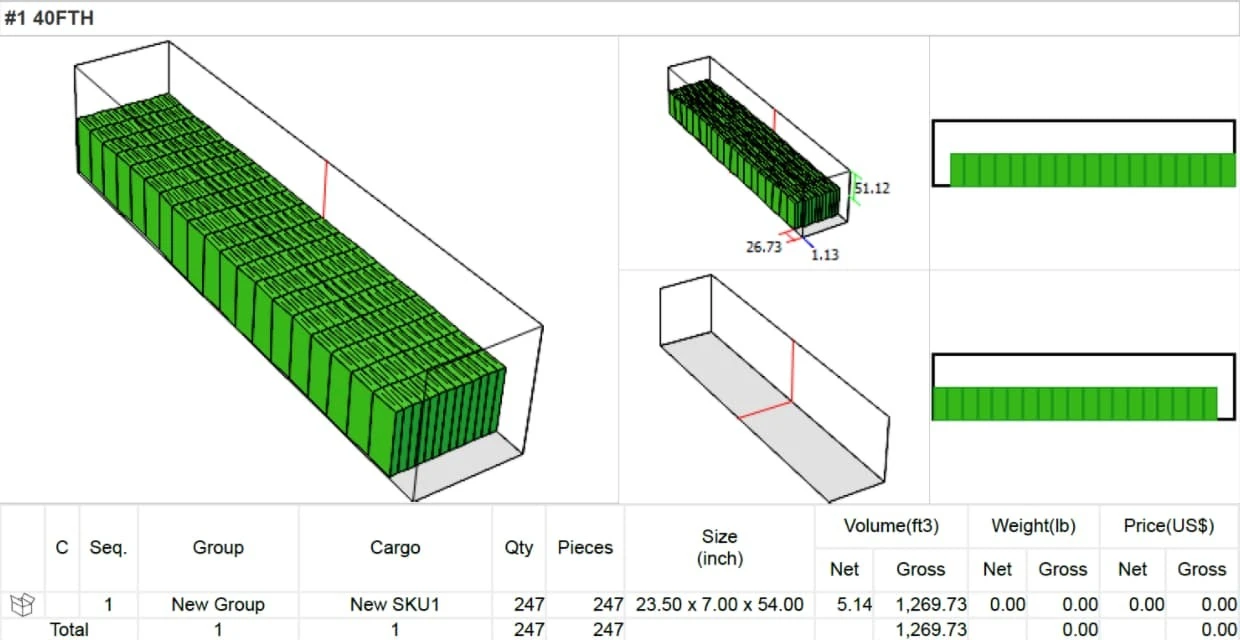

Load the container with boxes standing up vertically. In this case, 247 cartons would fit in a 1 x 40-foot container. The boxes would be clampable with virtually no chance of refusal. There would not be any additional charges to transload the container but given the lower count the cost per unit would be $20.47.

Solution #3:

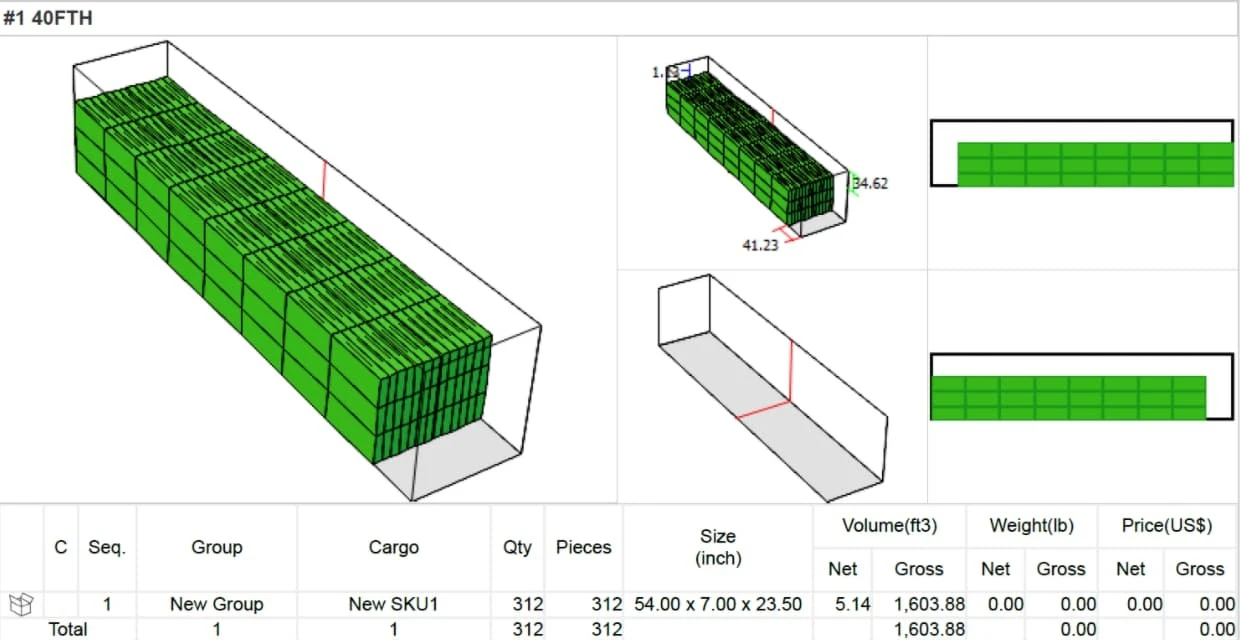

Load the container with boxes standing up horizontally, which would allow for three rows of boxes. The factory could fit 312 units in each container. The height of the top row would be over shoulder height but since the boxes would be clampable, the chances of refusal would be minimal. The landed cost per unit would be $16.20.

Option #1 was instantly eliminated, as it was obviously the least cost-effective route. The client was able to compare options #2 and #3, and ultimately decided to go with option #3. This choice entailed a moderate risk of being refused, but had the lowest cost per unit. The factory was given instructions on how to load the container, according to the plan prepared by Freight Right’s team. The method was tested on the following few containers and no refusals were recorded. Later, this option was chosen as the permanent solution for said client.

Should Amazon restrictions change, the client still has option #2 to fall back on, with only a slight increase in cost per unit.

The Shipper’s Responsibilities:

Use and build acceptable pallet shipments

Label pallets in compliance with Amazon’s requirements

Provide the Bill of Lading

Schedule a Delivery

Provide carrier with Amazon’s reference ID’s, and tracking (PRO) numbers

The Carrier’s Responsibilities:

Obtain Amazon’s reference ID’s, shipment IDs, and tracking (PRO) numbers

Schedule a delivery appointment ahead of time for expected shipments

Comply with vehicle condition requirements

*The carrier should only request an appointment upon all shipments to be delivered have been identified and determined. The carrier can only request up to 7 appointments for each shipment.

*If multiple appointments are made for one physical delivery, these bookings may be canceled, deleted, or delayed.

Box Limitations: One single less-than-truckload (LTL) shipment cannot exceed 5,000 boxes. In the case that the shipper has more than 5,000 boxes, they must create a second LTL shipment.

Use 40” x 48” four-way access wooden pallets

- Unacceptable: pallets made out of weak material like plastic, particleboard, or cardboard.

If one single large unit cannot fit on this pallet, without overhanging the edges, the shipper may use a size and type of pallet that is best suitable for that single unit.

Use GMA Grade B pallets for shipment (can be made out of plywood, lumber, composite, etc.)

If shipping groceries, ship them on GMA 1A Grade pallets

For Health & Personal Care and Beauty products, only GMA 1A & 1B Grade pallets are acceptable

Do not ship on pallets that are in poor condition

Unacceptable: damaged and broken pallets. These can be refused and rejected at the seller’s expense

The shipper must load all partnered carrier shipments onto pallets unless they are delivered by small parcel carriers. All non-partnered carrier shipments that can’t be sent on pallets, then they are required to be floor-loaded.

Make sure that all cartons on the pallet comply with Amazon’s shipment packaging requirements.

The Assembly Process:

Make sure that each pallet must have units that all belong to one shipment ID.

Please shipping boxes (intended to be sold together- sets) that weigh over 100 pounds on one single pallet. You can also clamp them together. All units on each pallet must belong to the same shipment ID.

Place single items that cannot be clamped together on their own pallets. An example of this is furniture that weighs more than 100 pounds and is more than 80” long or is more than 30” wide.

Height and Weight:

Make sure that the total weight of your pallet does not go over 1,500 pounds.

Make sure that single pallets are not taller than 72” tall (including the height of the pallet). This is so unless a single unit is taller than 72” tall.

You can pack a pallet to be up to 98” if it matches the requirements of Amazon’s “clampable” instructions.

Stack and Wrap:

Stack boxes by using ‘standard pallet stacking requirements.’

Do not bundle shipping boxes with bags, elastic materials, or extra straps.

Make sure that the product does not overhang from the edges of the pallets.

Stack and wrap all pallets in clear plastic stretch wrap, and label each pallet with “do not break down” or “do not break stretch wrap” note to the carrier.

Make sure that the stretch wrap completely holds the product on the pallet to avoid shifting during the transportation process.

Make sure that the products remain stable once the wrap is removed.

Label:

Make sure that every box on the shipment is labeled with a unique Shipment ID, as prompted by Amazon’s shipment label requirements.

Place shipment labels on all four sides of each wrapped pallet, outside of the stretch wrap.

Load:

Make sure that the overall height of the pallets allows at least 6” of clearance between the top of the pallet and the roof of the container.

Use air bags to allow at least 3” between container stacks and walls during transit.

Use metal straps or safety nets to prevent the load from shifting or falling during transit.

Amazon fulfillment centers accept double stacked pallets, only if they are packed safely to load and unload and does not damage the product during transport. Any shipper is allowed to use the double stacking method, only if they adhere to the following guidelines:

Double-stacks do not exceed 100” of height (including the height of the pallet).

There is at least a 6” space between the top of the pallet and the container roof. This is to make sure that the pallets can be unloaded safely with a forklift.

The boxes are stacked evenly from one corner to the other and do not overhang the edges of the pallet.

The pallets are stacked in a way that will not disturb the unloading process.

Use air bags to make sure that there is at least a 3” space between container stacks and walls, during transit.

Use metal straps or safety nets to make sure that the load does not shift or fall during transit.

Make sure that there is at least 8” of clearance between the last row of boxes/pallets and the container doors, to engage the dock leveler.

Make sure to provide shipment labels on the outside stretch wrap, on all four sides of the pallet.

Print and place shipment labels on every box in the pallet.

Place the shipping labels squarely (straight) to make sure that the forklift driver can see it when lifting the pallet.

If the pallet contains only one ASIN, label it as “Single ASIN Pallet.”

If and when shipping multiple SKUs on a single pallet, place each SKU separately, so it is easily distinguishable upon arrival to the Amazon Fulfillment Center.

*There are additional Amazon carrier shipping label requirements when the shipper sends to a local fulfillment center under Amazon’s Shipping program. Each Amazon carrier label is unique and must be applied with an FBA shipment label. When loading the trailer, the pallets must be placed in a way that the Amazon carrier and FBA shipment labels are all facing the door.

Every time you ship less-than-truckload (LTL) or full truckload (FTL), the shipper is required to provide a valid bill of lading (BOL) to the carrier, so that a delivery appointment can be scheduled. Any shipment BOL that does not adhere to the following requirements can be refused and rejected upon delivery.

This information must be typed and printed out and not handwritten. Amazon prefers the standard BOL template, which makes sure that the shipment is easy to identify and receive faster. If the carrier does not provide a template of the BOL, make sure that you as the shipper, provide this information:

All Amazon reference IDs and Shipment IDs

Name of the seller

Origin Address (street, city, state, zip)

Seller’s legal name

The name of the carrier, along with their standard carrier alpha code (SCAC)

Carrier’s shipper reference number (PRO #)

Unit quantity information (pallet, box, each #)

Trailer and seal number (only for truckload shipment)

“Shipper load and count” or SLC if the trailer has been loaded, locked and sealed without allowing the driver to count/inspect the content of the shipment

Pallet and box quantity

Freight charge terms

The carrier is responsible for scheduling an advanced delivery appointment to Amazon’s fulfillment centers. It is both the shipper and the carrier’s responsibility to complete any required steps prior to requesting a delivery appointment.

General Warnings:

The carrier must follow Amazon’s delivery requirements and adhere to safety standards.

In the case that unforeseen weather is affecting the delivery schedules, the carrier must communicate this to Amazon. Any schedule changes will be made based on a given warehouse’s availability.

For all less-than-truckload (LTL) and full truckload (FTL) deliveries, Amazon fulfillment centers prefer shipment on pallets. If for any reason, this cannot be done, the carrier must choose “floor loaded” as the load type when booking a delivery appointment at the fulfillment center.

*If you are using Amazon’s Partnered Carrier Program for either LTL & FTL deliveries, place your shipment on pallets, as Amazon’s partnered carriers do not accept floor loaded shipment or shipment not on pallets.

The carrier must have a completed list of Amazon reference IDs, shipment IDs and tracking (PRO) numbers included on or along with the Bill of Lading (BOL). Amazon requires this information when scheduling a delivery appointment at the fulfillment centers.

The carrier must tell Amazon the box and pallet counts before scheduling an appointment.

The fulfillment center may request unit counts if the carrier has a record of them. Floor-loaded trailers must be indicated on the carrier freight bill and when requesting a delivery appointment.

All delivery vehicles delivering to Amazon’s fulfillment centers must follow these guidelines:

The floor of the vehicle must be able to hold the weight of a fully-laden pallet jack.

The floor of the vehicle must be well-maintained, free from holes or any other unsafe conditions.

The vehicle must be sealed, clean, and free of strong, unpleasant smells, especially during the delivery of food and health care products.

Unless they’re used to secure a load, straps must be firmly tightened to the vehicle to make sure that it poses no harm to fulfillment center employees.

Corrugated floors, refrigerated trailers are not permitted.

*Amazon associates can refuse to check in any trailer, truck, shipment if they cannot safely remove the product from the deck. Amazon normally forwards this information to the seller’s email address, letting them know that the delivery has been unsuccessful.

Factory address

Delivery address (If delivering to Amazon FBA, please provide the 4-digit Facility Code)

Description of goods (Include HS Code if available)

Value of goods

Advise if you have imported to the United States before

Do you have a continuous customs bond?

How often do you import to the U.S.?

How often do you plan to import in the next year?